Looking to automate your warehouse inventory counting? Warehouse robots are revolutionizing how businesses manage their inventory, offering unprecedented accuracy and efficiency. In this guide, we’ll explore how modern warehouse robotics solutions are transforming inventory management through AI and advanced automation.

In today’s fast-paced logistics environment, warehouse managers face increasing pressure to maintain accurate inventory counts while maximizing operational efficiency. Traditional manual inventory counting methods are time-consuming, prone to errors, and often require significant labor resources. The solution? Smart warehouse robots that combine artificial intelligence with advanced mobility solutions.

The Evolution of Warehouse Robots

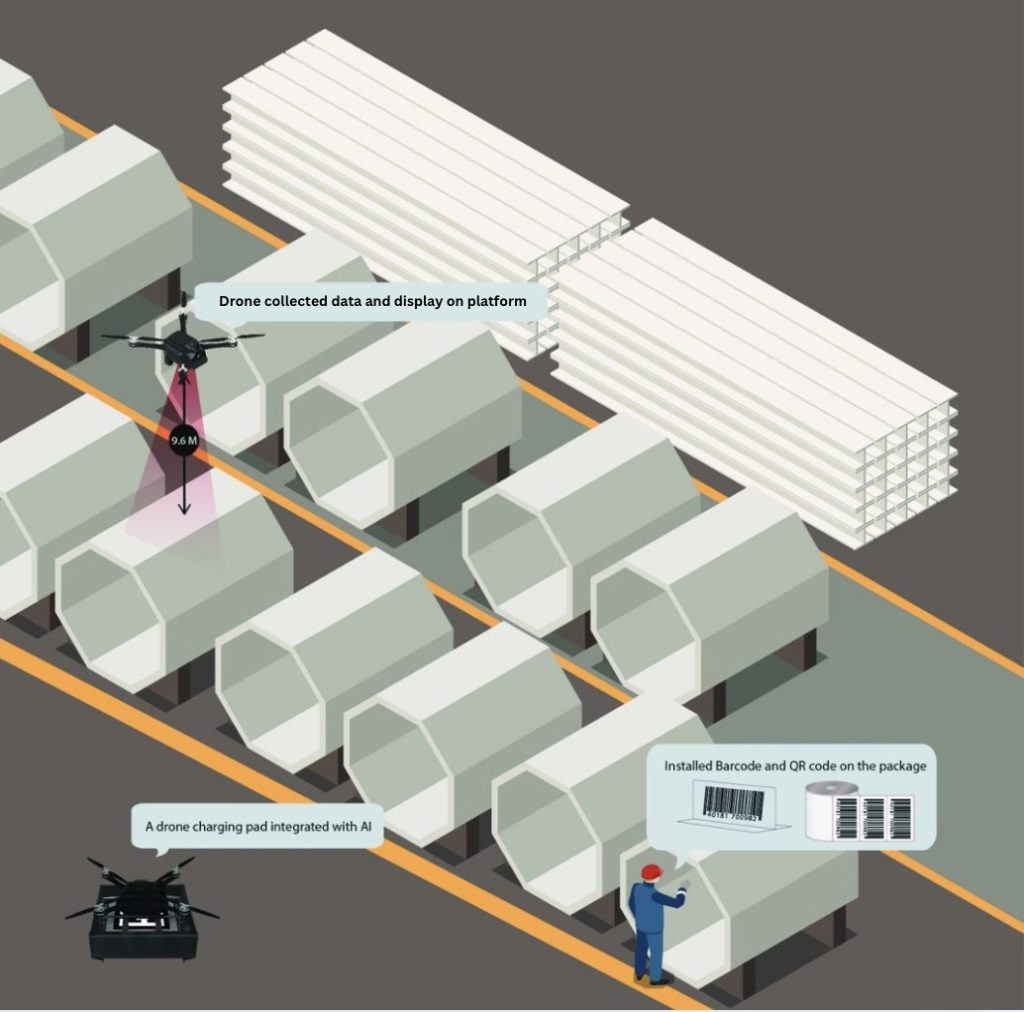

Warehouse robotics has come a long way from simple automated guided vehicles (AGVs). Modern robotic solutions now incorporate sophisticated technologies such as computer vision, machine learning, and aerial mobility to perform complex inventory management tasks. These advanced robots can navigate warehouse environments autonomously, scan barcodes and QR codes, and even perform visual inspection of inventory items.

Robot Implementation Considerations

Infrastructure Requirements

When considering robotic solutions for warehouse inventory management, organizations should evaluate:

- Network connectivity throughout the facility

- Adequate lighting for visual inspection systems

- Clear pathways for robot navigation

- Integration capabilities with existing WMS

Return on Investment (ROI)

- Initial equipment and installation costs

- Reduced labor expenses

- Improved inventory accuracy

- Enhanced operational efficiency

- Potential reduction in safety incidents

Innovative Approaches to Automated Inventory Counting

- Scan barcodes and QR codes on pallets from multiple angles

- Verify product locations

- Capture detailed images for AI-powered inventory counting

- Access hard-to-reach areas without requiring lift equipment

One of the most groundbreaking developments in warehouse robotics is the integration of aerial technology. These advanced robots can navigate through narrow aisles and reach high storage locations that would be challenging for traditional ground-based robots or human workers. By combining aerial mobility with high-resolution cameras and AI-powered computer vision, the warehouse drone solution can:

AI-Powered Visual Inspection

The Warehouse Drone leverage sophisticated AI algorithms to perform tasks that once required human intervention. For example, when dealing with bulk materials like steel rolls, these systems can:

- Automatically count inventory items using computer vision

- Detect product dimensions and characteristics

- Identify damaged or misplaced items

- Generate detailed inventory reports with minimal human intervention

Improved Accuracy

The warehouse drone can increase accuracy of inventory counting, significantly reducing discrepancies and associated costs. This high level of accuracy is particularly valuable for warehouses handling high-value items or maintaining just-in-time inventory systems.

Enhanced Safety

By deploying drone for inventory counting tasks, warehouses can reduce the need for workers to operate at heights or in potentially dangerous areas. This not only improves workplace safety but also reduces insurance costs and liability risks.

Increased Efficiency

The inventory management drone can operate continuously, performing counts during off-hours or weekends without requiring overtime labor. This continuous operation capability means:

- More frequent inventory checks

- Faster identification of discrepancies

- Reduced operational disruptions

- Lower labor costs

Online Platform for Data Access

The warehouse drone integrates with warehouse management systems (WMS) to provide inventory data. This integration enables:

- Immediate updates to inventory records

- Enhanced tracking of inventory movement

- Better decision-making through data analytics

Warehouse drone represents a significant leap forward in inventory management technology. By combining advanced mobility solutions with AI-powered systems, these robots offer unprecedented accuracy, efficiency, and safety in warehouse operations. As the technology continues to evolve, we can expect to see even more innovative applications that will further transform the warehouse management landscape.

For warehouse managers looking to stay competitive in an increasingly automated world, investigating robotic inventory management solutions could be the key to achieving operational excellence while reducing costs and improving accuracy.

Ready to Modernize Your Warehouse Operations?

Warehouse drones represent the future of inventory management, offering a powerful solution for businesses looking to improve accuracy, efficiency, and safety. Whether you’re managing a small warehouse or a large distribution center, robotic inventory solutions can help you stay competitive in today’s fast-paced logistics environment.

Want to learn more about implementing warehouse drone in your facility?

Contact Us